Hello, welcome to visit anhui Maanshan Zhicheng Machine &Electric Co.,Ltd!

SetHome | AddFavorite | Contact us

Maanshan Zhicheng Machine & Electric Co.,Ltd.

Contact: jian-hua Yang

Tel:13705554456

Address: Maanshan horry huashan district town village in yellow

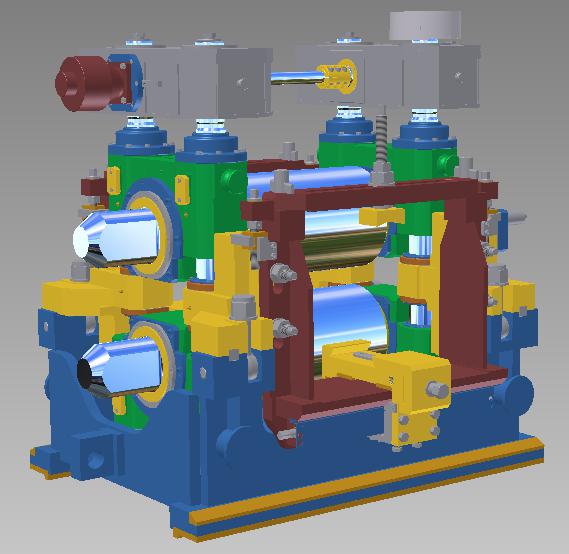

Short stress mill

Short stress mill

Leading models - bar, wire and section steel production lines;

Main features - short stress loop, small elastic deformation, high overall stiffness, rapid replacement;

1. Composition of the machine core:

The core of bar and wire rolling mill is mainly composed of roll gap adjusting device, roll system, pull rod assembly, mill stand, guide beam and so on. In order to prevent the axial movement of the rolls, the device for preventing the axial movement of the rolls is installed on the operating side of both the upper and lower rolls.

1. Roll gap adjusting device: It consists of hydraulic motor, transmission shaft, transmission side and operation side worm gear pair, bevel gear pair and so on. The transmission side and the operation side have one pair of worm and worm gear pairs, and the two sides of worm and worm gear pairs have one pair of bevel gear pairs. A bevel gear is installed at the upper end of each of the four pull rods in the rolling mill. The hydraulic motor drives the pull rod to rotate through the worm and worm gear pairs and the bevel gear pair. The pull rod drives the roll up and down through the inner screw mother of the bearing seat. Single roller bearing seat has opposite left and right rotation direction of the built-in nut, upper and lower roller bearing seat has opposite screw direction of the built-in nut on the same side, and upper and lower rollers rise and fall in reverse, so as to form a symmetrical adjustment of roll gap. The fixed rolling line reduces the production accidents and improves the mill operation rate. A clutch is arranged on the transmission shaft between the worm gear box on the transmission side and the worm gear box on the operation side, which is convenient for adjusting the roll gap on one side to ensure the level of the upper and lower rolls.

2. Roll system: It consists of rolls, four-row short cylindrical bearings, thrust bearings and axial adjusting devices. The driving side and the operating side of each roll are respectively supported by a four-row short cylindrical bearing. A thrust bearing is installed on the operating side of the roll to bear the axial load of the roll. The operation side of the upper roller is equipped with an axial adjusting device, which adopts a built-in structure consisting of worm, worm wheel, front and rear double threaded pairs. The manual rotating worm, worm wheel driven thrust bearing, inner ring of four row short cylindrical bearing, movable labyrinth and upper roller move axially together.

3. Tie rod assembly: It is composed of bearing seat, tie rod, intermediate support seat, etc. The bearing seat is built-in with a screw mother. The upper and lower bearing seats are connected by four tie rods fixed in the four intermediate support seats. The upper and lower rolls are balanced by elastic damper (half a year of service life) shock absorber, which can eliminate the thread clearance between screw nut and tie rod. Because the mill archway is cancelled, the stress line length is shortened and the radial spring of the mill is reduced due to the connection between the tie rod and the inner screw mother of the bearing seat. The bearing seat connected by tie rods makes the stress state of the roller bearing more reasonable, so it improves the bearing capacity, prolongs the service life of the bearing, and makes the operation of the roller bearing more stable. Short stress rolling mill has higher stiffness and rolling accuracy than other rolling mills.

4. Mill stand

Welded parts have compact structure, high rigidity and strength.

5. Guide beam

A. Fixed guide;

B. Radial and axial adjustment functions;

C. The sprinkler pipe with upper and lower rolls on the guide beam.

2. Main commonly used models:

Model parameter 650550450350

Maximum opening (load) 740630490390

Minimum load 620520410330

Roll neck 300280230200

Roller length (mm) 760760700650

Maximum rolling force (kN) 3100280023001500

Frame transverse displacement (mm) 785 + 350 + 325 + 300

Axial adjustment (mm)+4+4+3+3

3. Characteristics:

1. Pressure device:

Equipped with a large speed than manual adjustment device, the adjustment is more labor-saving and easier;

2. Mill stand:

The improved stand is used in conjunction with the new frame guide device to make the mill more stable and rigid.

3. Roll system:

It has an axial adjusting device.

With an axial positioning device, there is no axial movement.

4. Tie rod assembly:

The double nut structure of main nut and auxiliary nut is adopted, and the thread clearance between the pull rod and the main nut is eliminated by the balance force produced by the balancing element (butterfly spring or damper) to improve the rolling accuracy.

With spherical cushion structure, the roll box can adapt itself to the rolling process, so that the bearing force distribution is more uniform, and the bearing life can be significantly improved.

5. New frame guide device:

The new frame guide device has upper and lower clamping function, which makes the guide fixed more firmly.

The rigid connection between the frame and the stand makes the rolling mill body more reliable and more resistant to impact force.

Because of the use of the guide frame, the restraint points of the stand are reduced, and the assembly and disassembly of rolls are more convenient.

6. It can realize rapid roll change and greatly improve the working rate of rolling mill.

Copyright ©Maanshan Zhicheng Electromechanical Co., Ltd Address :Horry town huang village in Anhui province Maanshan huashan area

TEL:0555-3151761 Phone :13705554456 The url :www.ahzcjd.com/

Email

:zcjdgs@163.com For the record,

:皖ICP备19005449号-1 Technical support

:Operation network

Mobile

Mobile Applet

Applet